Shop Floor Mngmt - Types of Productions

Continuous improvement is better than delayed perfection.

Mark Twain

Shop floor is a part of machine-tool industries. Every shop floor is different. The type of shop floor entirely depends upon kind of product manufactured, the way a process is executed or the type of machinery used. These production types are classified as per the industry classification in various countries.

Let us understand in detail some more things about the type of productions and the type of shop floors.

Productions as per Types of Industries

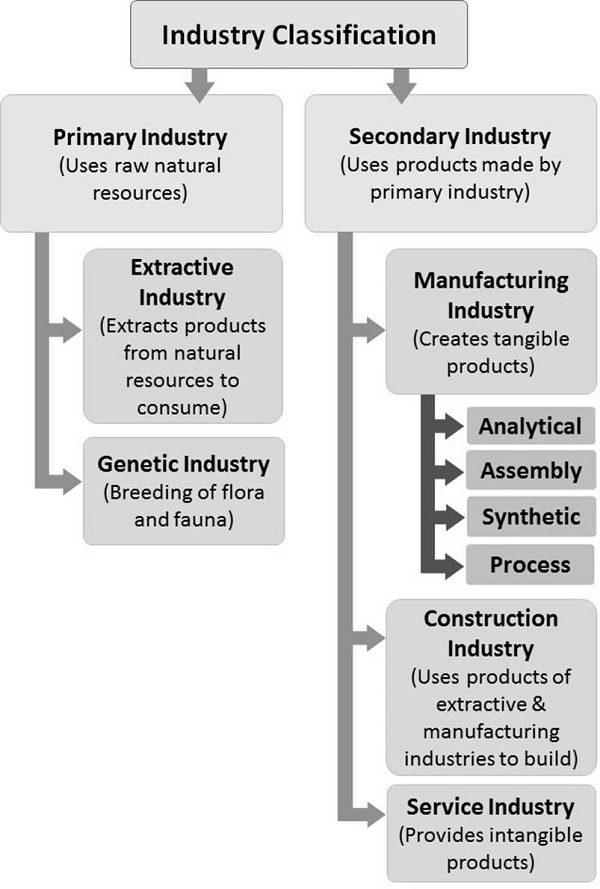

To see what all types of products are typically produced, let us first understand the types of industries creating those products. The industries are classified into Primary and Secondary.

Primary Industries

They are the ones which use natural resources and consume them directly. They are further separated into two types −

Extracting − These industries involve extracting minerals, water and drawing out different types of products from Earth, Forests and the Oceans. For example, Agriculture, Mining, Lumbering are the businesses belonging to the extracting industry.

Genetic − These include businesses working in multiplying animals and plants. Animal husbandries, plant nurseries, fish farming, poultry are some examples of businesses belonging to the genetic industry.

Secondary Industries

They are mainly based on the primary industries for their input resources. They are further divided into the following types −

Manufacturing − They use raw material or semi-finished products to transform them into fine products.

Analytical − A raw material is analyzed and separated.

Assembly − Various components are joined together to create a fine product.

Synthetic − Multiple raw products are combined to make a new product.

Process − The raw material is passed through various stages to create a product.

Construction − They use products of primary as well as secondary industries to construct infrastructure.

Service − These industries do not manufacture any tangible product, but they work on providing intangible products such as experience and satisfaction.

From the industry classification diagram, it is seen that not all industries have shop floors. The work of extraction, genetic and construction industries goes on the sites. The service industry does not have a specific work area; because a service providing business can be executed from a house or can be in the airlines too.

It is the manufacturing industry which has a shop floor as an important part of its execution.

Shop Floor Types

The shop floor types can be understood from the following perspectives −

Product Quantity Perspective

There are two types of this perspective that implies in what quantity the product is manufactured −

-

Mass Production − Mass production involves manufacturing of the standardized products efficiently in large quantities. This is also called as flow production or continuous production. The shop floors for mass production are equipped with assembly lines, machinery and power at a large scale.

For example − Fast Food Manufacturing. The food items are produced in large numbers, where the cost of manufacturing a single product is very less.

-

Scant Production − It involves creating the product in a sufficient number. It is also called small-volume production.

For example, production of pure platinum.

Process Perspective

Process perspective is concerned with how the final product is made. Following are the basic types of process perspective −

Assembly − On this shop floor, the components are assembled to manufacture a product. These components are already manufactured and can be directly employed as a part of another product. These type of shop floors have assembly lines and a linear movement of the product. The workers stand in that order and perform operation on the product. For example, Car manufacturing, electric or electronic equipment manufacturing shop floors.

Analytical Process − It involves breaking of a basic raw material into components, which can be used independently. For example, a refinery breaks down crude oil to get aviation fuel, gasoline, diesel, and petroleum wax.

Synthetic Process − It involves using various raw materials or other products to manufacture a good quality product. For example, Shampoo, paints and various cosmetic products manufacturing.

Processing − As the name suggests, it involves processing of raw or semi-raw materials through various stages to manufacture a superior product. The material changes its form and appearance while undergoing processing. The processing shop floor contains heavy machinery and expert workers at each stage. For example, textile and cheese manufacturing shop floors.

Machinery Layout Perspective

This perspective of looking at a shop floor tells us about how the machinery is laid out on the shop floor.

Job Shop − A job shop is nothing but a processing center. In this type of a shop floor, the tools and machinery is placed as per the type of jobs the expert workers need to perform. The products become finer by going through various job shops. There are multiple jobs done at a job shop and then the product moves ahead to the next job shop. Hence, the sequence of product movement and tracking of progress are vital on this kind of a shop floor.

Flow Shop − It is the site where machinery and equipment are placed by the order of processing the product. The product is seen gradually taking shape from where it started till it takes the final shape and is ready. Estimation of product volume is important on these shop floors. If the volume is changed, it is difficult to respond to it and keep the workers motivation.

In the next chapter, we will discuss regarding the different types of shop floor layouts.