- SAP MM Tutorial

- SAP MM- Home

- SAP MM - Overview

- SAP MM - Screen Navigation

- SAP MM - Procurement Process

- SAP MM - Organization Structure

- SAP MM - Enterprise Structure

- SAP MM - Defining Structure

- SAP MM - Organizational Units

- SAP MM - Master Data

- SAP MM - Purchase Info Record

- SAP MM - Source Determination/List

- SAP MM - Procurement Cycle

- SAP MM - Purchase Requisition

- SAP MM - Request for Quotation

- SAP MM - Outline Agreement

- SAP MM - Quota Arrangement

- SAP MM - Posting Period

- SAP MM - Purchase Order Types

- SAP MM - Inventory Management

- SAP MM - Invoice Verification

- SAP MM - Service Management

- SAP MM - Valuation

- SAP MM - Account Determination

- SAP MM - Configuration

- SAP MM - Transaction codes

- SAP MM Useful Resources

- SAP MM - Questions & Answers

- SAP MM - Quick Guide

- SAP MM - Useful Resources

- SAP MM - Discussion

SAP MM - Quota Arrangement

A particular material can be procured from different vendors depending upon the requirement. So, total requirement of a material is distributed to different vendors i.e. quota is assigned to each source of supply. This is known as quota arrangement. The key points about quota arrangement are as follows −

Quota arrangement divides the total requirement of material among certain sources of supply i.e. vendors and then assigns quota to each source.

This particular quota specifies the portion of material that is to be procured from assigned vendor or source.

Quota rating is used to determine the amount of material that is to be assigned to particular source or vendor. The source with lowest quota rating represents the valid source.

Quota rating can be calculated by following formula:

Quota rating = (Quota Allocated Quantity + Quota Base Quantity)/Quota

Where

Quota Allocated Quantity is total quantity from all orders that is procured from a particular source.

Quota Base Quantity is quantity from new source of supply.

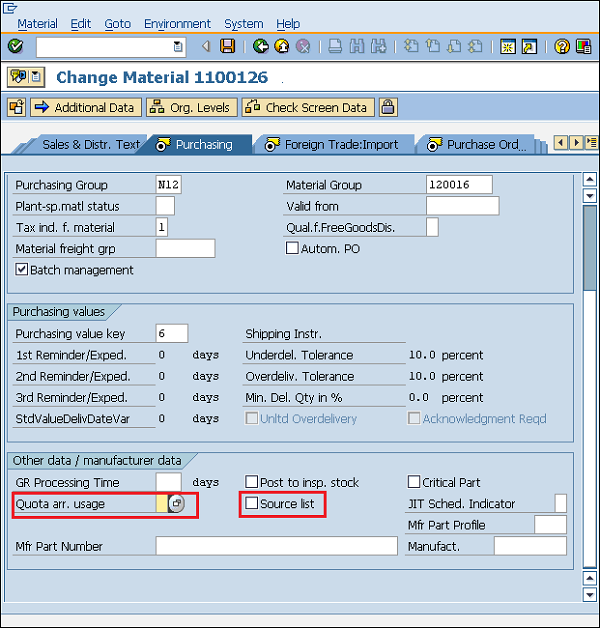

Quota is total requirement of material that is given to a particular source of supply.The mandatory setting before creating quota is info record and source list should be maintained for the particular material. Also in material master, source list and quota arrangement usage check box should be checked. This setting can be made in material master by following the below steps −

Go to TCode MM03. In purchasing view check the quota arrangement usage and source list. Setting is now maintained for quota arrangement.

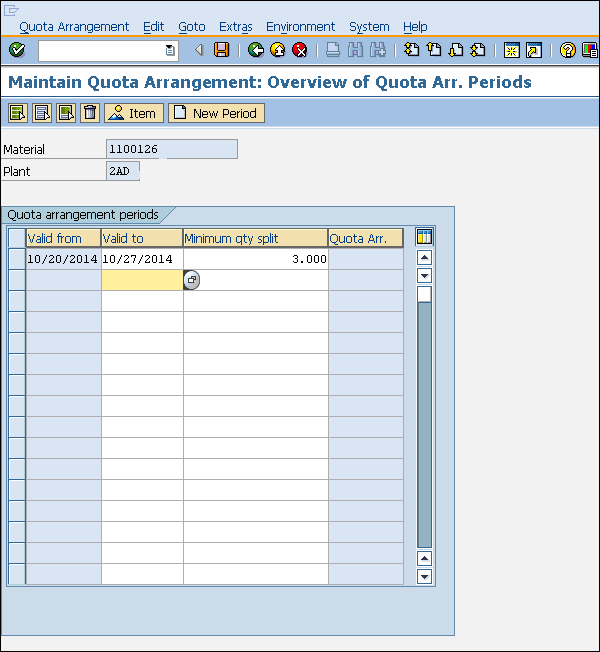

Create Quota Arrangement

Quota arrangement divides the total requirement of a material among certain sources of supply i.e. vendors. Quota arrangement can be created by following the below steps.

Path to create Quota Arrangement:

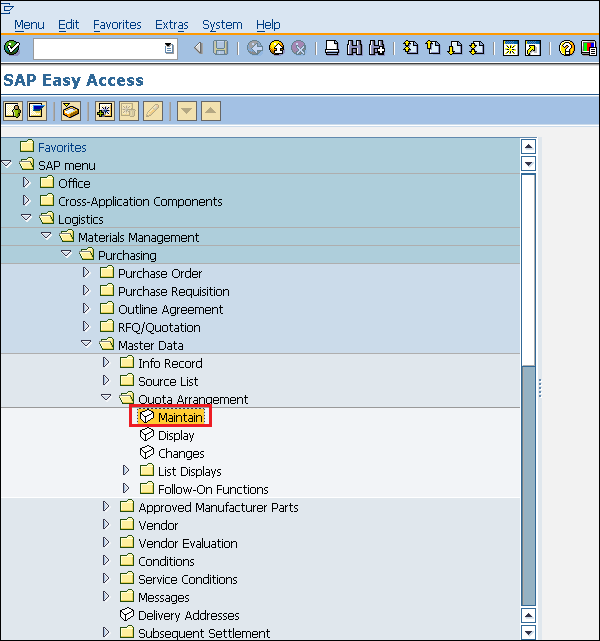

Logistics => Materials Management => Purchasing => Master Data => Quota Arrangement => Maintain

TCode: MEQ1

On Sap Menu screen select Maintain execute icon by following the above step.

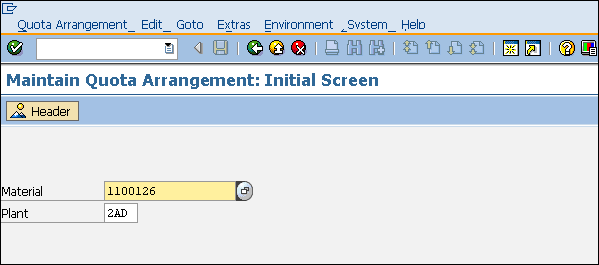

Enter the material number and plant for which quota arrangement needs to be maintained.

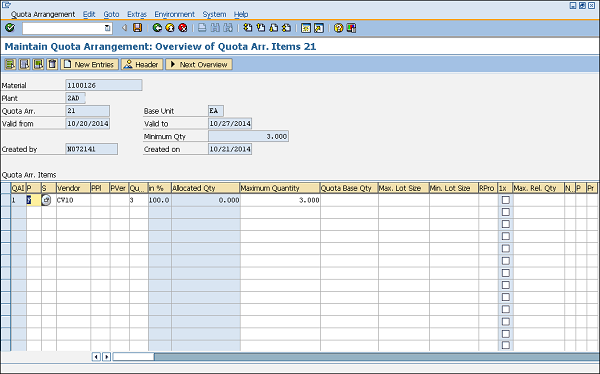

Provide the dates like valid from and valid to and also quantity split.

Enter the name of vendors and assigned allocated quantity to them. Click on save. Quota arrangement is now maintained for the particular material.